|

|||||||||||||||||||||||||||||||||||||||

|

- Machine & technology

- Technology & Options

- Specifications

- Floor Plans

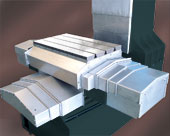

| Mini - High Speed High Precision CNC Machining Center |

| Cut the most complicated parts. |

| All casting structures undergo precise and detailed designs, analysis and calculations by CAD/CAE software. | Closed and sealed casting with damping sand inside can absorb all the vibration from high speed machining. the heavy machine design can bear the high acceleration and deceleration without vibration. Both result in smooth and fine surface on complicate 3d profile. |

| High Rigidity and High Precision Structural Design - Reliable Accuracy Foundation. |

|

|

|

||

| All three-axis use linear motion guides XY25mm / Z32mm that generate more smooth motion under lower friction. | No counter weight Z-Axis driving system design eliminates all the oscillation from speed upwards-downards motion. | The high rigidity direct-drive coupling can transmit torque efficiently and reduce the torsion displacement to minimum. These guarantee the accurate cutting of sharp edge during the high speed machining. |

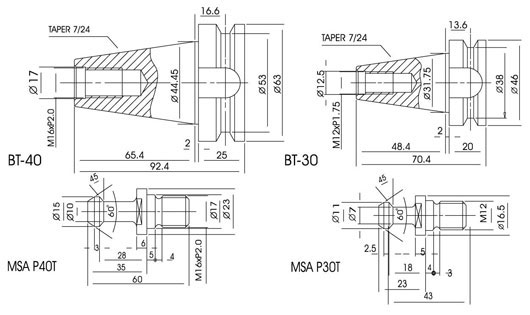

Modularized multi-purposes spindle designs fit all requests from different users. From heavy duty cutting BT40 spindle to high speed & high accuracy ceramic spindle can provide a total solution to all machining operations. |

|

|

|

| BT30 build-in ceramic high-speed spindle combines both milling and engraving operations with one machine. | BT40 timing belt spindle provides giggler horsepower also allows installing optional central coolant through spindle. |

|

|

|

| The design of fully support linear motion guide reduces the gravity deformation during mechanical movement to a minimum. | Closed box designed base with three points supports provides high rigidity and accuracy foundation. |

| Mini - High Speed High Precision CNC Machining Center |

| Cut the most complicated parts. |

| 3-Axis Telescope Covers | Standard Armless Type 10 tools ATC | Laser Calibration before Delivery | ||

|

|

|

||

| Better protection system and more effective for getting rid of cutting chips while using 3-axis telescope covers. | Standard armless 10 tools ATC provides a stable and reliable tool changing mechanism. | Laser Calibration Instruments is used on every machine before delivery to customers to guarantee the positioning accuracy after a minimum of 48 hours dry running. |

| Ball-Bar Testing | Optional Coolant Through Spindle device | Optional Arm Type 20 tools ATC | ||

|

|

|

||

| ARIX CNC can provide a ball Bar Testing to replace actual circular cutting Test to adjust the relevant electrical parameters. | BT40 Spindle can enhance Drilling effciency with optional Coolant Though Spindle unit. | Faster tools changing mechanism suitable for parts machining. |

| Optional High Performance 4th Axis Rotary Table | Optional Universal Functions 5th Axis tilt Table | Optional Spindle Configurations |

||

|

|

|

||

| With the high rigidity and high precision of 4th axis rotary table can provides stable and reliable rotation and index accuracy. | The simultaneous motion of 5 Axis provides universal maching applications. | BT30-12,000RPM / BT30-24,000RPM |

| Optional Tool Length Setter 1 | Optional Tool Length Setter 2 | Optional Spindle Oil Cooler | ||

|

|

|

||

| Covered Tool Length setter allows automatic tool length offset by CNC unit. | "Renishaw" Tool Length Seter can measure and offset the tool length and radius even though the tool is rotating. | Spindle Oil Cooler keeps the operating temperature constant and prolongs spindle's life / accuracy and etc. |

| V450 Specifications | ( ) is the optional items |

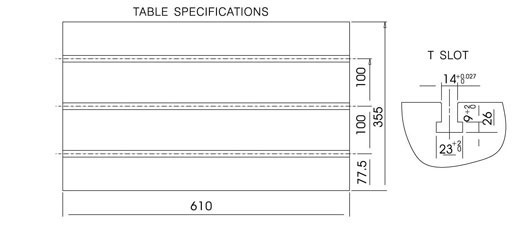

| Table | Working surface | 355 x 610 mm |

| T slot | 14 mm x 100 mmx 3 | |

| Loads Capacity | 150 KGS | |

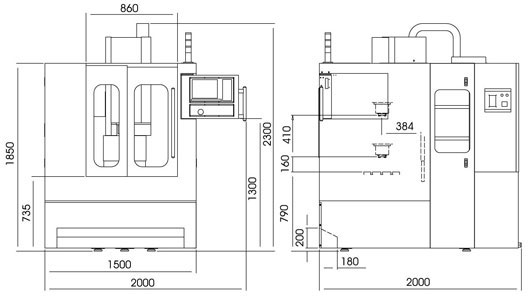

| Travel | Stroke(X x Y x Z ) | 450 x 350 x 350 mm (Z 410mm) |

| Center to Column | 410 mm | |

| Nose to Table | 160 - 560 mm | |

| Spindle | Spindle Table | BT30 (BT40) |

| Spindle Speed | 10,000 RPM (8,000/12,000/24,000 RPM) | |

| Spindle Horse Power | 5 HP (7.5 HP ) | |

| Transverse | Rapid X,Y axis | 20 M/Min |

| Rapid Z axis | 10 M/Min (20 M/Min ) | |

| Max. Feed | 10 M/Min | |

| Servo Motor Power | 1 KW (2 KW ) | |

| Accuracy | Positioning accuracy | + / -5um |

| Repeatability | 2um | |

| Machine | Dimension W x D x H | 1500 x 2000 x 1950 |

| Weight | 2800 KGS | |

| Power Source | 15 KVA |

| ★ Design and specifications are subject to change without prior notice. |

| Standard Accessories | Optional Accessories |

| 1.Tools box | 1.Rigid Tapping |

| 2.Automatic lubrication system | 2.BT40 - 12,000 RPM |

| 3.Full close cover | 3.BT30 - 24,000 RPM |

| 4.Work lamp and alarm lamp | 4.Rotary table 125mm |

| 5.Arm Type 20/16 tools ATC | |

| 6.Hard driver | |

| 7.Ethernet | |

| 8.Five axis table 125mm | |

| 9.Coolant Through Spindle device | |

| 10.Tool Length Setter. |