|

|||||||||||||||||||||||||||||||||||||||

|

|

- Machine & technology

- Technology & Options

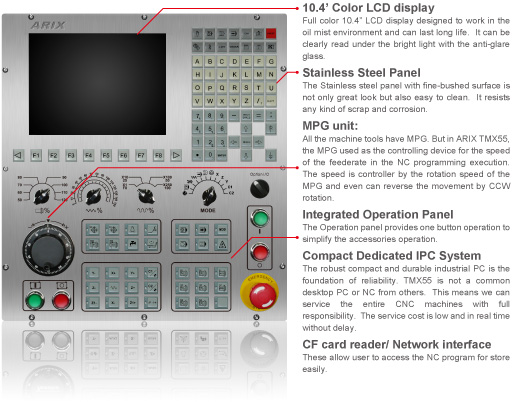

- Controls

- Specifications

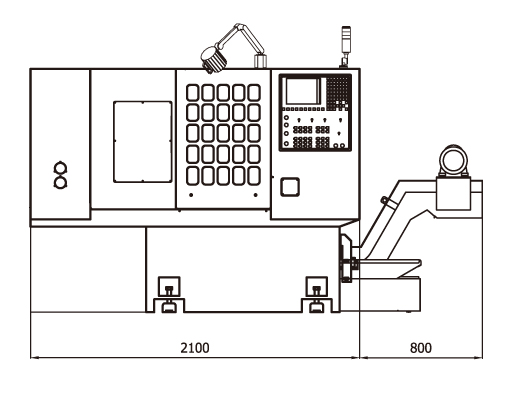

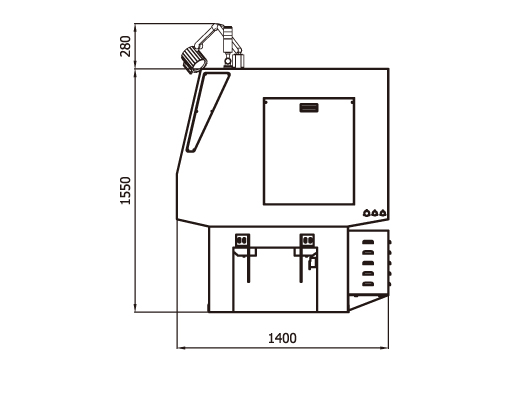

- Floor Plans

| High performance Steel Bar/Part Turning Center | |

|

|

|

|

GTL-42 Watch the video |

|

|

|

|||

| The Jaw chuck with gantry turret: The jaw chuck of 5” and 6” optional give the cutting range more flexible. | The Standard servo turret gives a accurate and speedy tool change. The hydranlic programmable tailstock wwith 150 mm manual stroke. |

|

|

|

||

| The standard part onveyor gets the production fully automation. | The cooling system for Hydraulic system | The large symmetrical head stock can bear bigger spindle up to 60mm capacity. |

|

Optional |  |

||

| The mineral stone base absorbs all the cutting vibration and generate super finish surface. | Oil Mister |

|

|

|

||

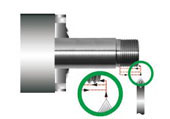

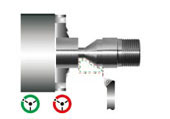

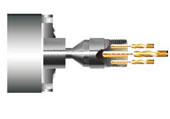

| The two steps hydraulic brake that can ensure the smooth C axis motion for machining in light braking force. The heavy braking can stop and take all the vibration from milling operations. | Live Tools Turret give capacity of milling |

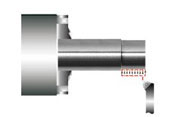

The coolant through drill option cuts the good finish holes. |

| Durable and Compact Hardwares |

Arix CNC TMX hardware has become more compact and reliable. The slimline operator panel has an extremely low mounting depth. High contrast and good readability even from extreme angle of vision make operation easier. All the keys arrangement is optimized for the operation on the NCL series with bar feeder. |

|

| Easy Progmminng Teach-In Functions |

|

|

|

||

| TURNING (STRAIGHT AND TAPER) |

FACING (STRAIGHT AND TAPER) |

THREADING (STRAIGHT, TAPER AND MULTIPLE) |

||

| Input the profile data from the blueprint. Press the simulation key to generate the graphic tool path. | Input the specific parameters for this operation according to the graphic guide. | For straight, taper or facial type of threads can be multiple as well. |

|

|

|

||

| MPG SIMULATION | END DRILLING | GROOVING (LONGITTUDINAL AND AXIAL) |

||

| After the machining program is loaded, select the MPG mode to let the NC program be executed according to the MPG rotaion speed. | Input the start, end point and drilling conditions to generate the NC program. | Do both longitudinal and axial grooving combining roughing and finishing. |

| Turning Milling Machine Specifications | ( ) is the optional items |

| Specifications | GTL-30 | GTL-42 | GTL-60 | |

| Capacity | Maximum turning diameter | |||

| Maximum turning length | 200 mm | 200 mm | 200 mm | |

| Bar work capacity | ||||

| Chuck size | 4 inch | 6 inch | 8 inch | |

| Spindle | Spindle nose | A2-4 | A2-5 | A2-6 |

| Spindle speed | 40~6000 rpm | 40~4000 rpm | 40~4000 rpm | |

| Spindle bore | ||||

| Spindle front bearing inner diameter | ||||

| Spindle motor power | 7.5 kw | 7.5 kw | 7.5 kw/11 kw | |

| Axes | X-axis stroke | 120 mm | 120 mm | 220 mm |

| Z-axis stroke | 255 mm | 255 mm | 380 mm | |

| X Axis rapid speed | 15 M/min | 15 M/min | 15 M/min | |

| Z Axis rapid speed | 15 M/min | 15 M/min | 15 M/min | |

| X Axis ball screw diameter x pitch | 5 mm | 5 mm | 5 mm | |

| Z Axis ball screw diameter x pitch | 5 mm | 5 mm | 5 mm | |

| X Axis linear guide size | 25 mm | 25 mm | 25 mm | |

| Z axis linear guide size | 25 mm | 25 mm | 25 mm | |

| X axis servo motor power | 1 kw | 1 kw | 1 kw | |

| Z axis servo motor power | 1 kw | 1 kw | 1 kw | |

| Turret | Turret type | Servo | Servo | Servo |

| Number of stations | 8 | 8 | 8 | |

| O.D. tools shank size | 20x20mm | 20x20mm | 20x20mm | |

| I.D. tool shank size | ||||

| Turret indexing time (1 station) |

2 sec | 2 sec | 2 sec | |

| Tailstock | Quill diameter | 55 mm | 55 mm | 55 mm |

| I.D. Taper | MT4 | MT4 | MT4 | |

| Tailstock stroke | 80 mm | 80 mm | 80 mm | |

| Others | Hydraulic pump motor power | 1 HP | 1 HP | 1 HP |

| Coolant pump motor power | 1/4 HP | 1/4 HP | 1/4 HP | |

| Coolant tank capacity | 170 L | 170 L | 170 L | |

| Accuracy | Spindle runout | 0.01 | 0.01 | 0.01 |

| Positioning accuracy | 0.005 | 0.005 | 0.005 | |

| Repatability | 0.005 | 0.005 | 0.005 | |

| Floor space | 3000 x 1300mm | 3000 x 1300mm | 3000 x 1300mm | |

| Dimension | Machine height | 1500 mm | 1500 mm | 1500 mm |

| Machine weight | 3000 kg | 3700 kg | 4000 kg | |

| ★ Design and specifications are subject to change without prior notice. |

| Standard Accessories | Optional Accessories |

| ‧Operative Lamp ‧Tool Box ‧Automatic Lubricant System |

‧Auto Bar Feeder Machine ‧Transformer ‧Part Catcher ‧Chip Conveyor |